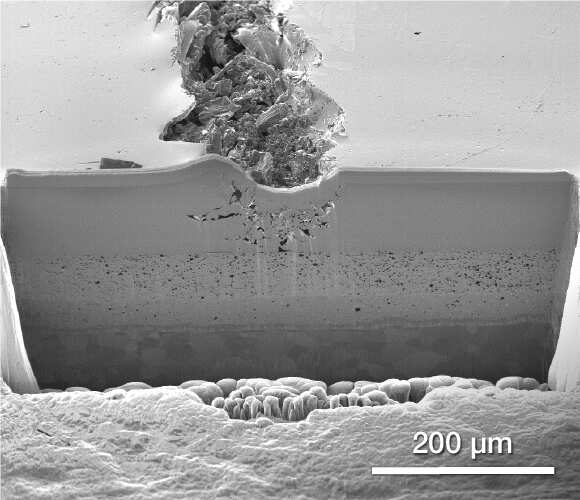

FIB Cross-section Milling

Instrument Type:

FEI Helios NanoLab 600i; ZEISS Crossbeam 540

Analytical Program:

Normal material -- 400 CHF/area

Ultra-hard/magnetic materials -- 600 CHF/area

Other samples -- Contact us for quotation

Instrument Type:

FEI Helios NanoLab 600i; ZEISS Crossbeam 540

Analytical Program:

Normal material -- 400 CHF/area

Ultra-hard/magnetic materials -- 600 CHF/area

Other samples -- Contact us for quotation

FIB (Focused Ion Beam) Milling is a technique that uses focused ion beams fornanoscale machining. It can be used to machine very small areas and is commonly used to produce electronic devices and nanostructures.In FIB cross-sectional milling, the ion beam is focused to a very small diameter, typically between a few nanometres and several hundred nanometres. The ion beam is directed onto the surface of the sample and theions collide with the sample atoms, causing the atoms on the sample surface to be reduced. As the ion beam is scanned across the sample surface, the desired structure can be formed.This technique can be used to create nanostructures such as nanowires, nanodots and nanopores. It can also be used to cut components such as metal wires and transistors in electronic devices.FIB cross-sectional milling is a very precise machining technique and therefore has important applications in the field of nanotechnology.

The sample should be small enough to fit into the FIB chamber, with blocks preferably less than 20 mm in length and width and less than 5 mm in height.

The sample should have a flat surface that can be mounted onthe FIB processing stand. Note that the sample may need to be cut or polished to obtain a flat surface.

The sample material should be compatible with FIB processing and typically includes metals, semiconductors, ceramics and biological samples. Samples should have good electrical conductivity or, if poorly conductive, should be coated with gold or carbon.

The ideal sample thickness depends on the specific application and the type of analysis to be performed.

The sample should be of high quality with minimal defects or damage that could interfere with FIB processing or TEM imaging.