Metallographic Sample Etching

Instrument Type:

Struers-LectroPol-5

Analytical Program:

Metallographic sample etching -- 30 CHF/sample

Instrument Type:

Struers-LectroPol-5

Analytical Program:

Metallographic sample etching -- 30 CHF/sample

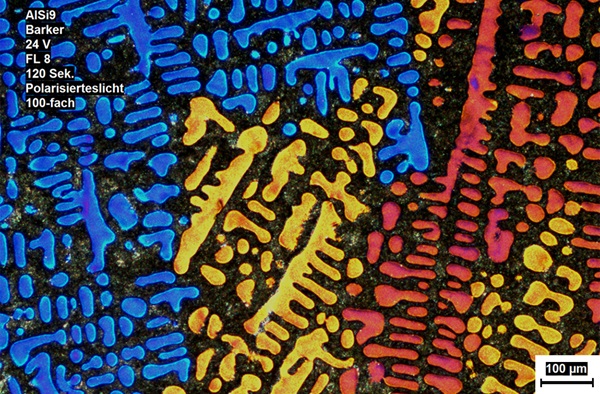

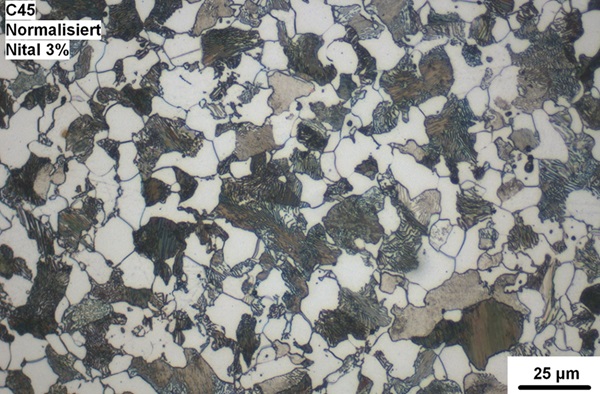

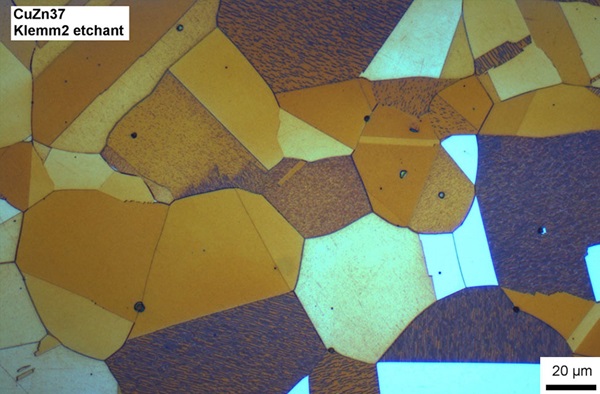

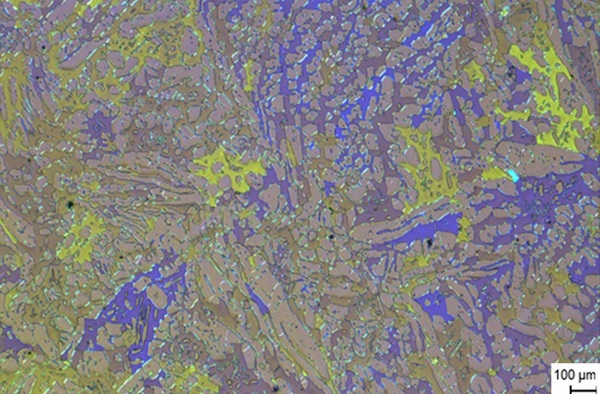

Metallographic sample etching is a method used to observe the organisation of metallic materials under a microscope. The etching of the sample causes varying degrees of corrosion on the surface of the sample, exposing the different metal structures so that they can be observed and analysed by microscopy. The main applications are in the following areas.

Microstructure analysis: Etching of metallographic specimens removes the corroded layer from the surface of the metal material, exposing different tissue structures, including grains, phase boundaries and inclusions, etc., so that the microstructure of the metal material can be observed and analysed by microscopy.

Preparation of metallographic specimens: Etching of metallographic specimens is one of the important steps in the preparation of metallographic specimens. By etching, a flat and smooth surface can be obtained, which is conducive to subsequent microscopic observation and analysis.

Quality control: Etching of metallographic specimens allows the quality of the metal material to be checked, including grain size, phase ratio and inclusion content. These parameters have a significant effect on the performance and life of the metal material, so etched specimens can be used to develop quality control programmes.

Metal corrosion studies: Etching of metallographic specimens can also be used to study the corrosion behaviour and mechanism of metallic materials. By selecting different etchants and controlling different etching conditions, the corrosion characteristics of metallic materials in different environments can be studied.

, V2A-lye or Adler etchant with hydrochloric acid.jpg)

1. Samples should be sufficiently free of surface dirt and oxidation. In general, samples can be polished using tools such as sandpaper and grinders until the surface is smooth and free of scratches and dents.

2. The sample should be of a thickness to ensure that the metallographic organisation is fully visible during the etching process. Typically, metallographic samples are sized from 10-30mm in diameter and 1-5mm thick and can be adjusted to suit specific needs.