Representive Results

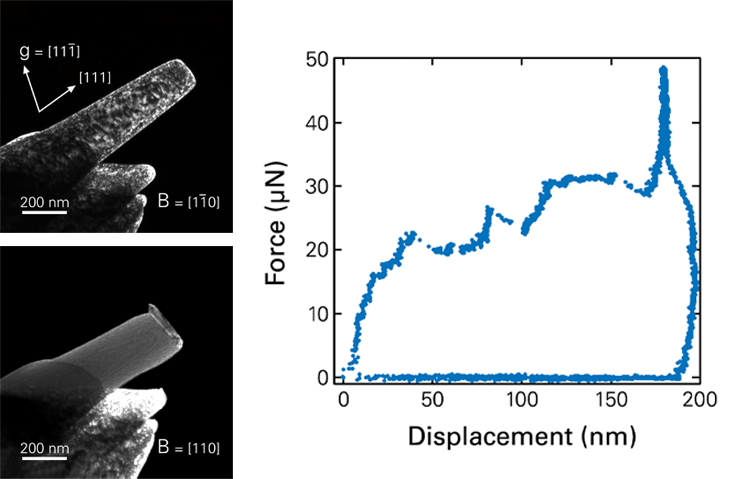

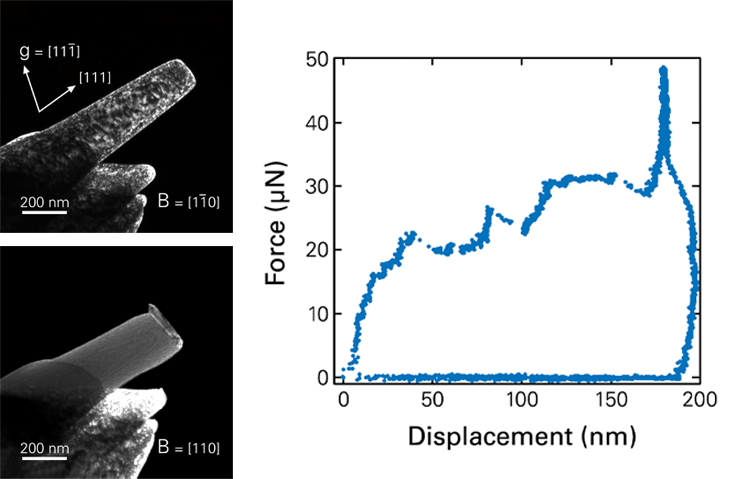

1. via TEM in-situ compression test to studytheplasticityofmetal

Caption: Dark-field TEM images of a Ni nanopillar beforeand after compression. The high

dislocation densityinitially observed in the pillar has disappeared uponcompression. Nature Materials 7,

115-119 (2007).

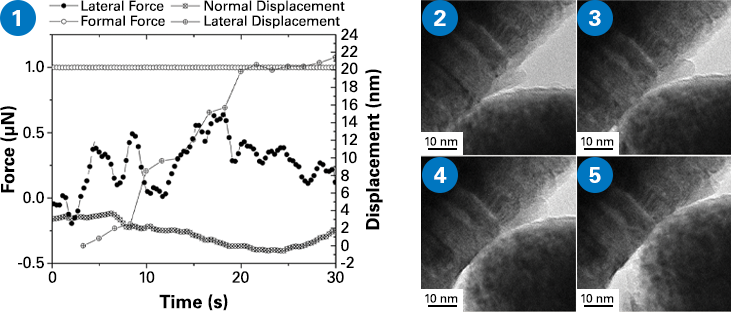

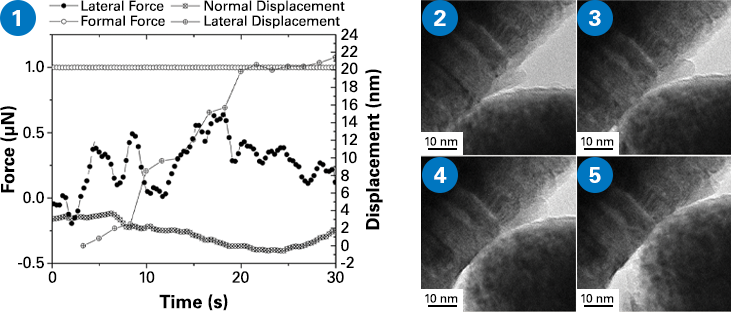

2. TEM in-situ nanoscratch test

Caption: Dark-field TEM images of a Ni nanopillar beforeand after compression. The high

dislocation densityinitially observed in the pillar has disappeared uponcompression. Nature Materials 7,

115-119 (2007).Application 2: TEM in-situ nanoscratch testCaption: An example 1 μN scratch test: (1)

Normal andlateral loads and displacements versus time and (2-5)corresponding frames from the in-situ TEM

video showingthe buckling of the DLC film in advance of the tip andflattening of the asperities in the

tops of the grains.

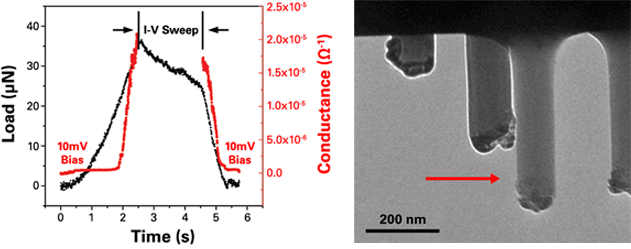

3. Simultaneous in-situ electrical andmechanical measurements during

nanoindentation,compression, or tensile loading

Caption: Electrical characterization during compression ofn-doped VLS-grown silicon

nanopillar. D.D. Stauffer, Ph.D.Thesis, “Deformation Mechanisms in Nanoscale BrittleMaterials,”

University of Minnesota (2011) pp. 150-152.

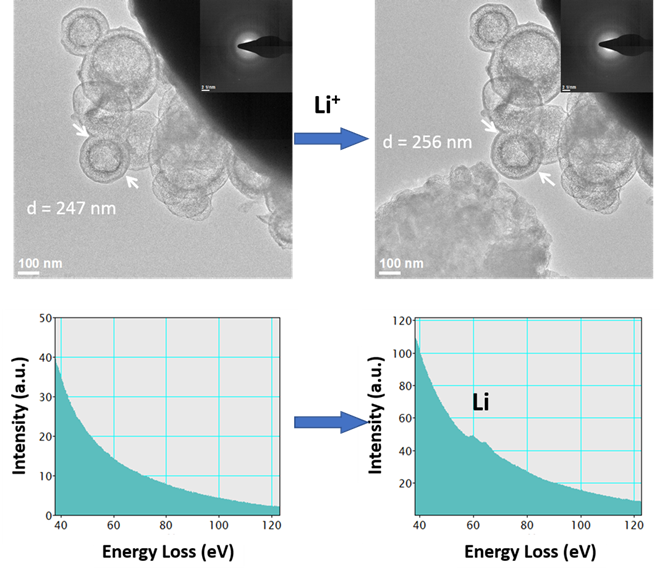

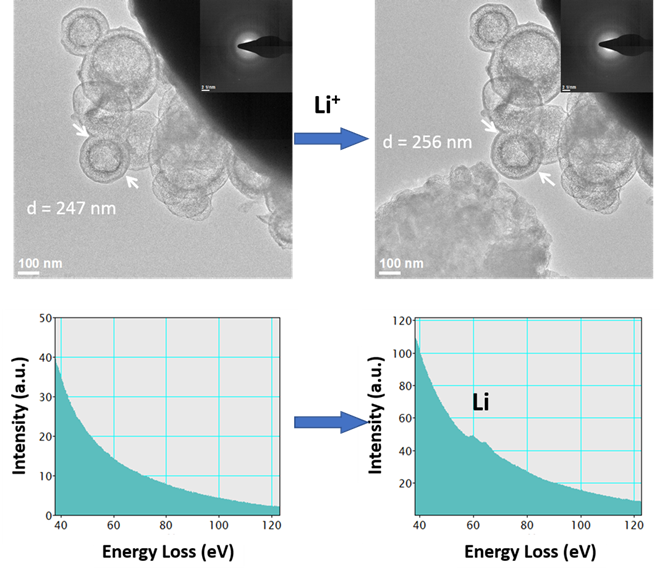

Core-shell electrochemical reaction TEM in-situ observationand measuring

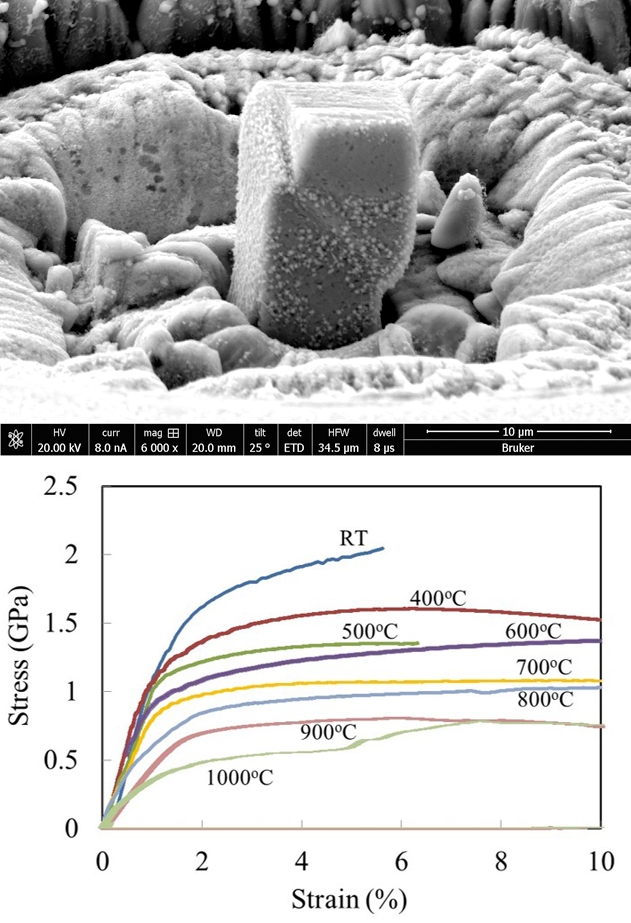

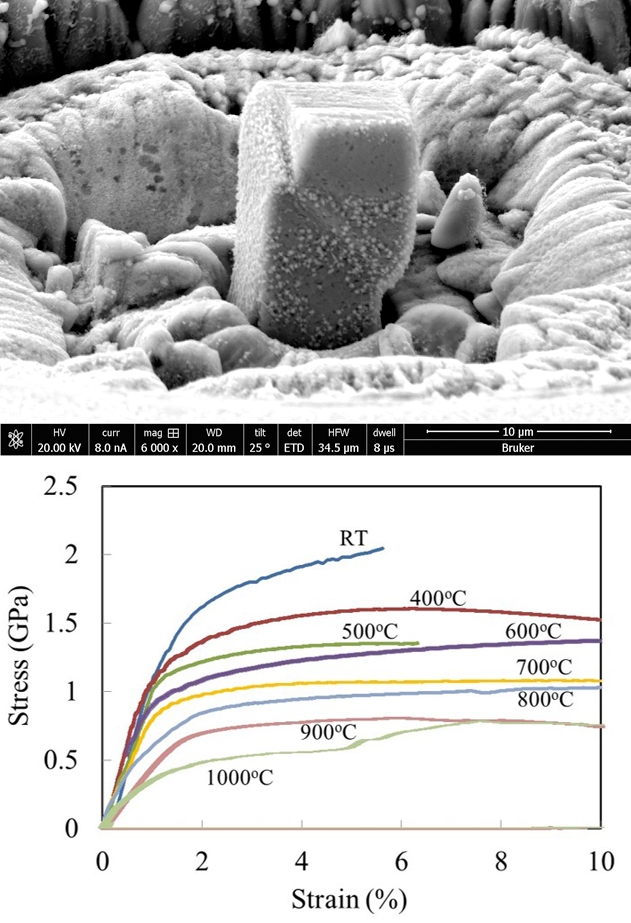

4. TEM in-situ test with heating

Caption: Pillar compression of Ni-Based superalloy at1000°C (top) and stress-strain

plots from in-situ pillarcompression tests of bond coatings (bottom).

Caption: TEM in-situ observation of oxides morphologyevolution during heating up